Step-by-Step Guide to Refining Gold from Electronics

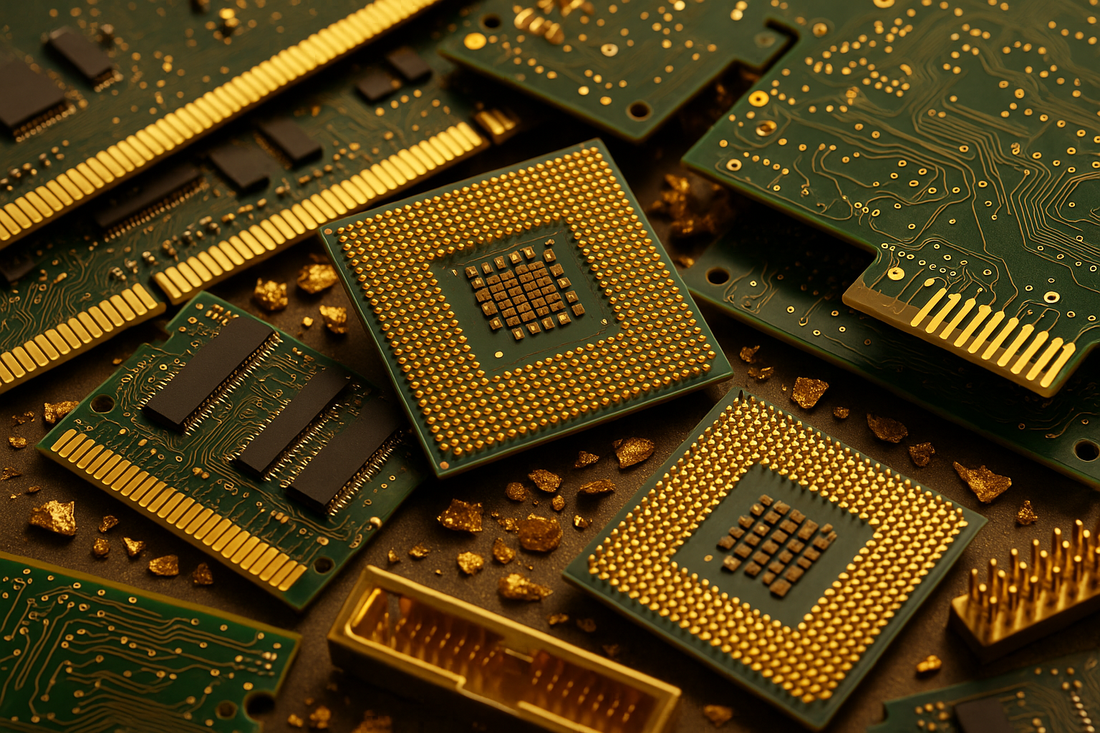

Old computers, phones, and other electronics contain small amounts of gold in their connectors, pins, and circuit boards. While each device only has a tiny fraction, with the right process, you can recover and refine this gold into a usable, pure form.

This step-by-step guide explains the basics of how to safely refine gold from e-waste using common refining chemicals like nitric acid and aqua regia.

Why Electronics Contain Gold

Gold is used in electronics because it resists corrosion and conducts electricity better than most metals. You’ll often find it in:

CPU pins and chip connectors

Motherboard contacts

RAM fingers

Cell phone SIM and memory card contacts

While the amount per piece is small, these parts can be processed together to recover grams of gold from scrap.

Safety First

Refining e-waste involves dangerous acids and toxic fumes. Always follow strict safety procedures:

Wear gloves, goggles, and acid-resistant clothing.

Work in a fume hood or outdoors in a well-ventilated area.

Keep neutralizers (like baking soda solution) ready in case of spills.

Never pour water into acid — always add acid to water when diluting.

⚠️ Important: Do not attempt this without proper safety equipment and legal compliance.

Step 1: Collect and Sort Scrap

Remove gold-plated parts (pins, fingers, connectors) from circuit boards.

Separate plastics and base metals as much as possible.

The cleaner your scrap, the easier refining will be.

Step 2: Dissolve Base Metals with Nitric Acid

Place the scrap into a beaker.

Add nitric acid (diluted with water, about 1:1).

Base metals like copper and zinc will dissolve, leaving gold foils or flakes floating.

Rinse the gold foils thoroughly with distilled water.

Step 3: Prepare Aqua Regia to Dissolve Gold

Mix 3 parts hydrochloric acid (HCl) with 1 part nitric acid (HNO₃).

Add your gold foils to this mixture.

The gold will dissolve, turning the solution a yellow/orange color.

Step 4: Neutralize Free Nitric Acid

Dissolve urea in warm water.

Slowly add it to the aqua regia until fizzing stops.

This step ensures nitric acid won’t interfere with the gold recovery.

Step 5: Precipitate the Gold

Add a sodium metabisulfite (SMB) solution to the neutralized aqua regia.

Gold will begin to fall out of the solution as a brown powder.

Let it sit overnight for full precipitation.

Step 6: Filter, Wash, and Dry

Filter the solution to collect gold powder.

Wash the powder with water, then with a small amount of ammonia, then rinse again with distilled water.

Dry completely.

Step 7: Melt the Gold

Place dried gold powder into a crucible.

Melt with a torch or furnace until it forms a solid button or bar.

You now have refined gold from electronic scrap.

Final Thoughts

Refining gold from electronics is a fascinating process that turns waste into something valuable. While it requires dangerous chemicals and careful handling, following the proper steps and safety measures can yield pure gold for collectors, jewelers, or investors.

👉 Ready to start? Explore our gold refining supplies including nitric acid, urea, sodium metabisulfite, testing kits, and precision scales.